Single Belt Conveyor

The Single 12” belt is designed to fit traditional conveyor pit dimensions to work in new construction of retrofit situations. One of the main benefits is fewer moving parts (no rollers, trap doors, roller up fork, etc.).

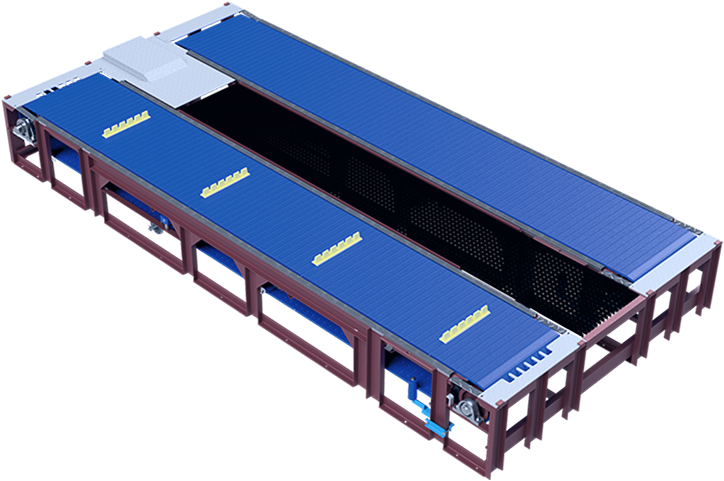

Dual Belt Conveyor

Dual 30 and 42″ belt conveyors are designed for more control of the vehicle when the driver is inside but less restriction on the type of vehicle being washed. Carrying all four tires affords more control; when the driver activates the brakes or turns the steering wheel, nothing happens.

144” (12’) Express Detail Belt Conveyor

The 12’ (144″) belt conveyor is designed for manually working on the exterior of a vehicle (hand washing and detailing). The belt stretches the full width of a car, and then some.